Backstage with Matthew: Building a Roman Icon

Tosca is a very important work for San Francisco Opera. It was in our inaugural season, it opened the Opera House in 1932 and it reopened the Opera House in 1997. We have performed the work over 150 times, but the production we have been using until now is a version of that 1923 production. Although our old Tosca has become a beloved friend, there are many who long to see a new interpretation of the piece, which is understandable after 96 years! I am so excited that we are embarking on a fascinating new interpretation of this most beloved opera, told in a thoughtful, nuanced, period, but psychologically probing way by director Shawna Lucey and designer Robert Innes Hopkins. This will be a production that we are proud and happy to see on our stage for the coming years and even decades.

Over the course of the coming months I look forward to taking you behind the scenes as we build a new legacy production, designed for the War Memorial stage, conceived for Bay Area audiences, and built in a way to last for decades to come. Opening night is October 3 and this new production is coming to life right here in the Bay Area, built by our phenomenally talented local artists, artisans and technicians. We’ll take a look at some of the costume work and props in the coming weeks, but today I wanted to give you a very early look at the scenery, being built down in our Burlingame Scene Shop.

The Scene Shop is about two weeks into the build process, which will last for another 14 weeks. They are working in reverse act-order, and so are starting with Act III and the sweeping walls of our stylized Castel Sant’Angelo, with an exquisite skyline of Rome in the background, and the iconic angel of St. Michael center stage. In this production the angel is turned around to face the city, horrified at the depravity and corruption that is happening within. Here is the latest design for Act III:

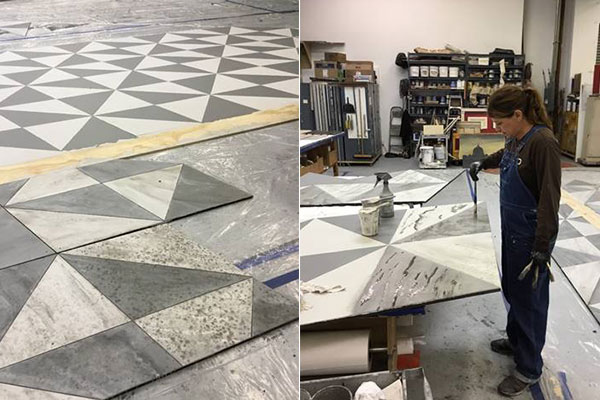

All of the acts will share a common floor and one of the important activities at the moment is to decide the specific paint effects. Steve McNally, our Scenic Artist in Charge, is working with his team, including Carrie Nardello to first create the geometric patterns of the floor in a tangram-like puzzle of interlocking shapes. They then apply a marbling effect, and finally add the patina of painted-on dirt: a patina that has to work for the three very discrete worlds of Tosca: a church, a palace and a prison! Here you can see Carrie at work on the marbleizing effect—creating a subtle and muted effect with a soft brush in black, white and grey paints, while using techniques like sprayed water to force the paint into swirling patterns.

Robert, our designer, arrives next week to look at finishes with the team, and he will work with them to ensure that the finishes and techniques are in line with the design, in plenty of time before everything is finalized. Once the painting on the floor is complete, the floor will be sealed and prepared for installation come the fall. It will be screwed into the actual stage floor, providing a stable, firm, textured marble tiled floor onto which Rome will be built!

The other main elements in the Scene Shop at the moment are the scenic ‘trucks’ that will become the foundation for the sweeping walls that you see in the model image above. These are built out of steel, cut with precision and welded together by Dylan Maxson. John Del Bono, our Scene-shop and Warehouse Foreman tells me that the calibration of these kinds of units is unparalleled with seamless communication, the technical department at the Opera House passing along CAD drawings (Computer Aided Design) to the Scene Shop who can then execute those to a minute fraction of an inch.

The scenic walls are being prepared out of wood, using scenic techniques passed down through generations and indicative of the incredible skill that we have in our crew. The kind of wood that you see here (for one of the canon positions) will be covered by muslin fabric before being painted – an old technique that can dramatically extend the life of scenery. The largest set piece in this act of Tosca will be 24 feet high. That is too high for our shop in Burlingame, so it will be built with cleverly hidden breaks, and assembled onstage.

John explains how thoughtfully the scenery is being constructed to ensure it can last for decades of wear and tear, not only in our house but in other companies should they rent our scenery. In addition to the muslin coverings, and the use of steel foundations, large structural units are being built to have at least one clean, hard edge that will allow our crew to maneuver the scenery during load-in, with units up to 1,200lb in weight. The skyline of Rome which you will see in Acts II and III, will be built in such a way that the fragile, carefully cut pieces, can be taken apart and stored in specially crafted boxes, minimizing the risk of these delicate pieces being broken in transit. These are the kinds of proactive measures that the crew are giving to our new Tosca to ensure that it moves seamlessly between the scene shop and the stage, and that it plays in a way that works well for our Opera House. That kind of synergy between the build and the use of a set is becoming a lost art as many companies close their scenic facilities, and I’m so grateful that San Francisco Opera has that capability to look at the holistic arc of a set. It makes a huge difference.

Elsewhere in the Scene Shop, Frederick Wielandt, our Assistant Master of Properties is beginning to build the plinth on which the angel of St. Michael stands and from which Tosca will jump. Pictured below is the plinth turned upside down, showing a trusted technique of mapping out scenery on the floor, and building it almost ‘in situ’ to fit the actual space. The wooden unit will ultimately be clad in sculpted Styrofoam which will allow for the creation of war-ravaged canon-shot effects, very important to this design.

Meanwhile, Steve McNally is beginning to work on some of the sculptural concepts and approaches that will be needed, particularly in Act I:

Take a look in detail at the model shot above and you will see many elements that need to be finely crafted to reflect the Baroque ornamentation of our church. (Our Act I is a design that marries the architecture of the actual venue, Sant’Andrea della Valle, with the intense color palette of the Duomo di San Giorgio in Ragusa, Sicily.)

Steve is busy preparing samples and mock-ups to show Robert when he visits next week, looking at color samples, the tromp-l’oeil effects that will allow us to paint some of the molding to appear three dimensional, and some of the techniques for building some of the statuary including elements like cherubs.

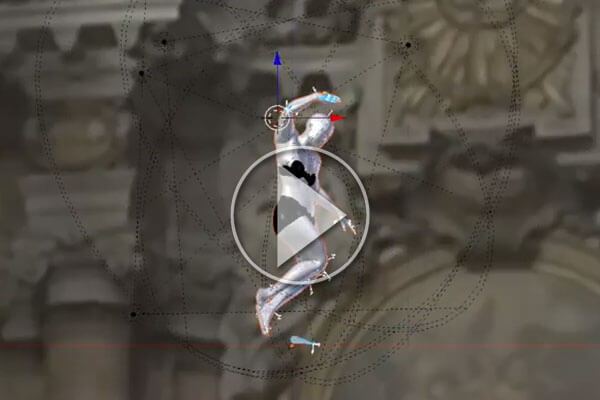

Using cutting-edge technology, and coopting software from animation, we can now use CNC technology (computer numerical control) to design things like the cherubs on a computer, and have a computer aided machine cut a precise replica of the image. You can see in this great video from Steve, how the cherub design comes to life in a process that begins on the computer, moves to a Styrofoam computer-aided sculpting, and is then finished by hand:

The larger angel of St. Michael will be built out of Styrofoam, fabric and plywood, although the clever design angles mean that only the back of the statue will need to be created in detail.

This is just the beginning of a fascinating process that we will check in on a number of times in the coming months. To have the craftsmanship within our Company to build a set like this epic Tosca is a major credit to the women and men who work in our Scene Shop and on our stage, and who bring a vast knowledge of techniques, of aesthetics, of tradition to their work. This would be a major undertaking for any scenic facility, and to see it develop with such positive energy right here in the Bay Area, with such creative problem solving, and such a sense of pride and joy is a great privilege for me.

We are just at the beginning of our Tosca journey—a major journey for San Francisco Opera and something I hope you will share my pride in. I look forward to peeking back the curtain on much more along the way with you and am so excited for you to see it in its finished state on the War Memorial stage in six months!